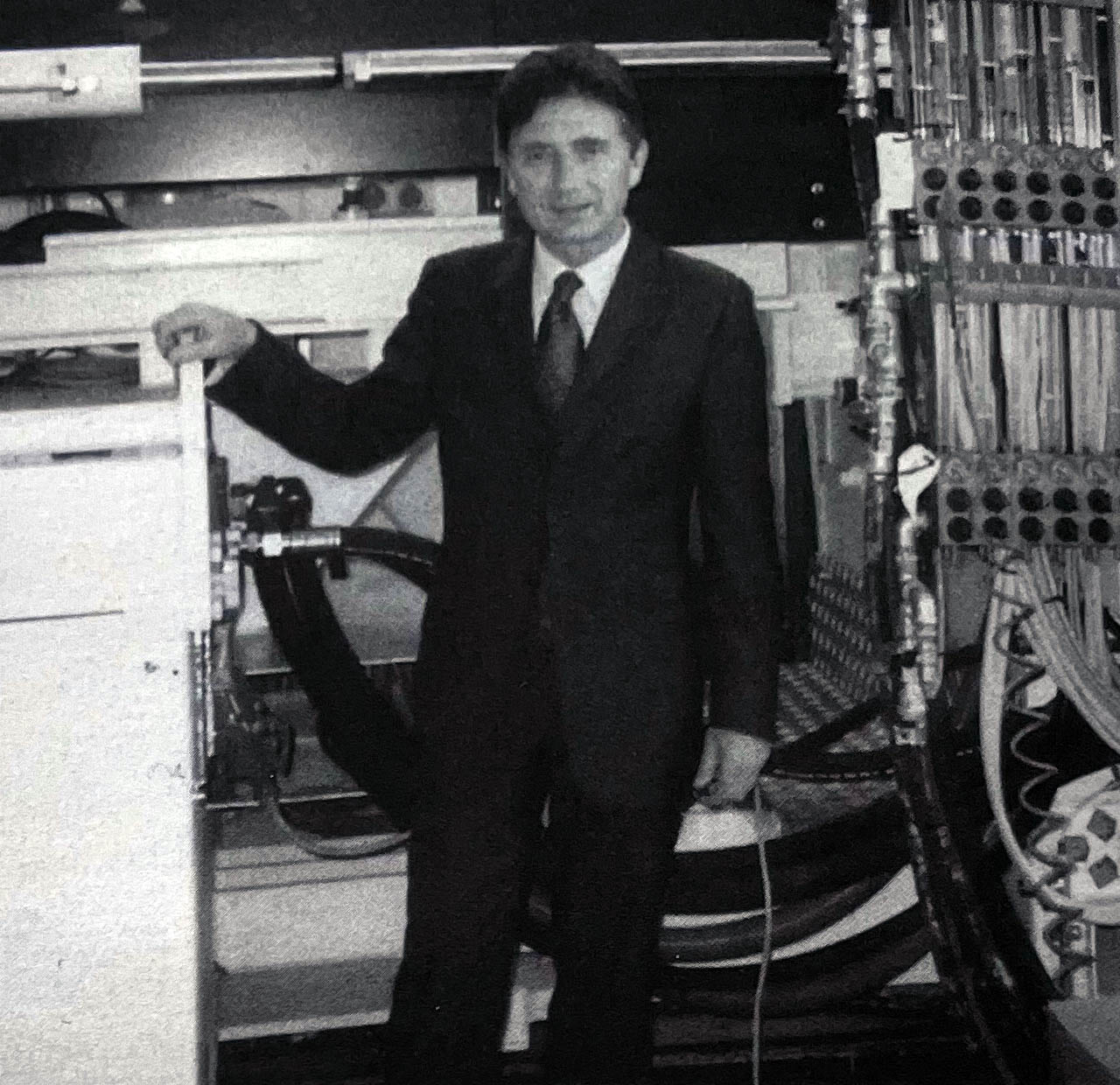

Grandad Pietro had a bicycle store at Niccone and it had been known throughout the valley since the early 20th century. In September 1945 he began to hire out irrigation pipes and motor pumps to farmers throughout Umbria. Rumour had at the time in the Umbertide area — says Pietro Giunti, grandson of the founder and current Chairman that cannon shells had been cut and then soldered to make pipes: this wasn’t necessarily just a myth.

The shop was a sort of emporium serving small scale farming establishments of the time: from then onwards — and it seems light years away compared to current activities the long business adventure began and developed.

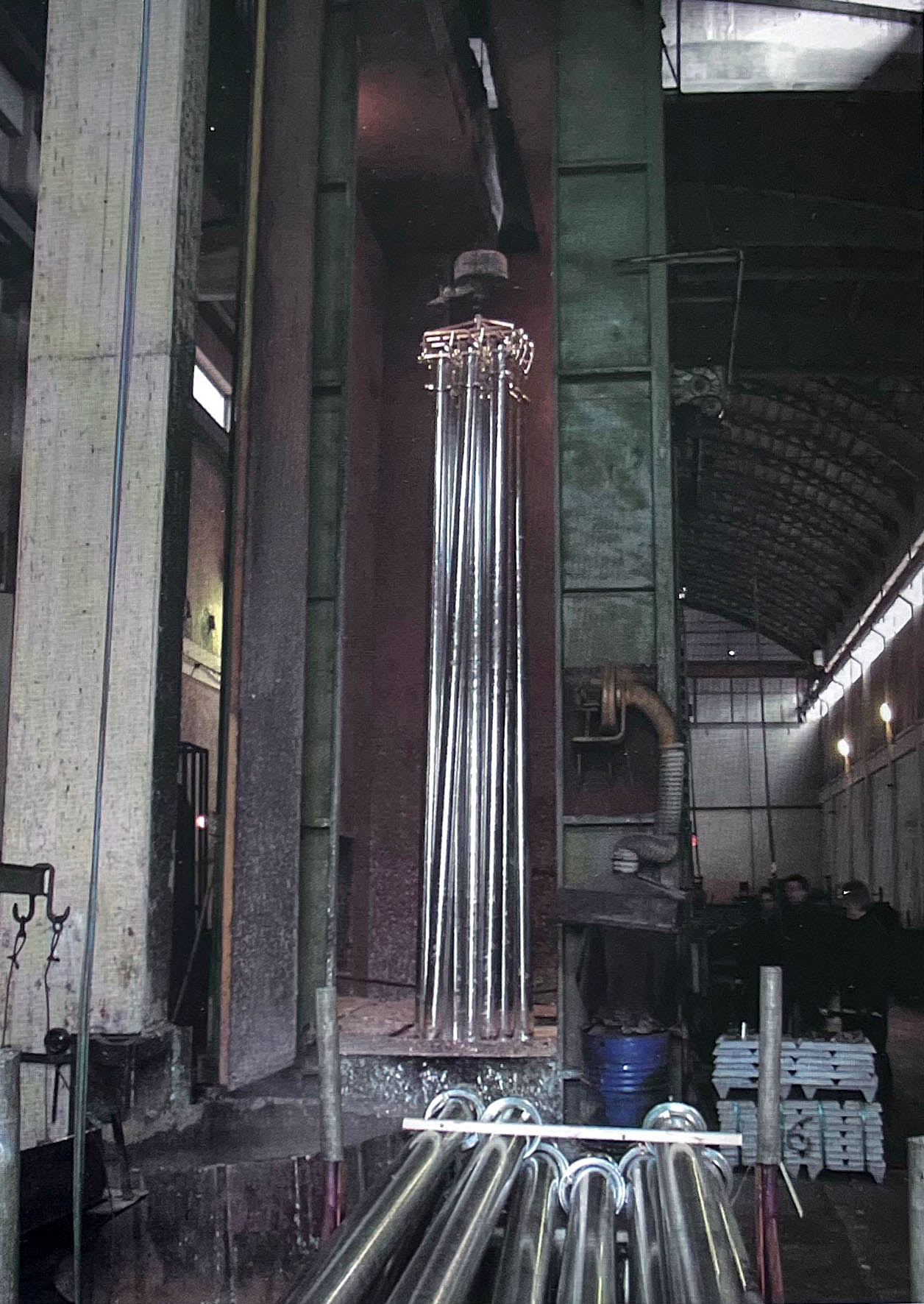

In the ’50s, to add to initial activities, as continuing irrigation was being introduced in Italian agriculture, the company developed an initial production line for steel pipes with quick couplings; two more lines were established a short time later.

But it was at the end of the ’70s that irrigation sys-tems began to be used by individual farms for different crops, as in the case of farms in the Emilia region where they were in use already 25 years earlier, although the systems were rather primitive. At this point irrigation evolved, became sophisticated and stopped using the pipes and turbines which had been used until then; a very important concept was introduced and it involved a method of irrigation management associated with production, and the Giunti company began to adjust to the different requirements on the national territory. For logistical reasons, it did so through three separate firms, each managed by a separate company and on Pietro each managed by a separate company and on Pietro indications COGEIR S.p.A was established at Caltagirone, I.M.G. at Pescara and CO.MI.R. at Perugia. The latter began to manufacture self-propelled irrigation machines as soon as they made their appearance on the market.